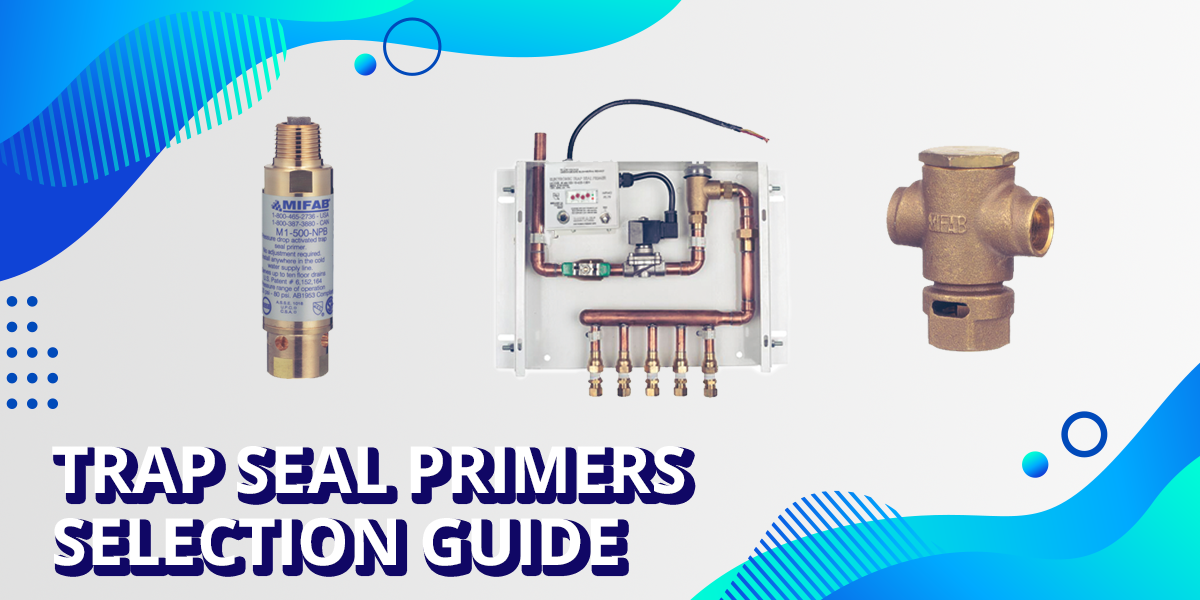

Which Trap Seal Primer is right for you?

With so many different types and brands of trap seal primers, it’s important to pick the right one for your projects as not all are the same. MIFAB wants to make that search easier for you.

Why are Trap Seal Primers needed in a plumbing system?

Trap seal primers are a necessity where floor drains are infrequently used and in areas such as mechanical and service rooms. Evaporation of water in floor drain traps allows sewer gas, pests and bacteria to enter the interior of the building. Trap Seal Primers are installed on a cold water supply line, and react to water flowing in the line to trigger, either by turbulence or pressure drop. Once a triggering event occurs, the primer will release water that is piped to a trap primer connector on or near the “P” trap being maintained.

How do I pick the right one?

There are four main types of trap seal primers, so it is important to know the differences between them as they each have their advantages and disadvantages. You want to make sure you pick the Trap Seal Primer that will meet your needs.

The four main types are:

1. Continuous Flow

2. Pressure Drop Activated

3. Flush Valve Operated

4. Electronic

Continuous flow trap seal primers are the original style of trap seal primers. They are typically constructed of cast brass or bronze with a neoprene rubber poppet float on the inside that rises upward as water flows through the primer. Continuous flow trap seal primers do not have any method of screening out line debris. This often results in their clogging and either flowing water continuously, or not at all. The volume of water that they discharge is directly related to the amount of water that continuously flows through them. For these reasons, pressure drop activated trap seal primers have become the selection of choice for specifiers.

Pressure drop activated trap seal primers are typically manufactured out of brass, as are MIFAB’s. The M-500 Pressure Drop Activated Brass Trap Seal Primers can be connected to any cold water line and will be automatically activated when a valve or faucet is on the line, is opened. They are made with a ½” MIP inlet connection and a ½” FIP outlet connection. They have an interior cartridge that seals when the line pressure is in a static state. It only requires a 3 PSI line pressure drop to activate the primer. The opening range for all of MIFAB’s M-500 Series of trap seal primers is 20 to 80 PSI.

Even better, there is also no precharge needed which makes cleaning and repairs simple. MIFAB has also made it easier for the inspection of water delivery by strategically placing four view holes to shine light through one side while looking into the other to see the water delivery. The stainless steel sediment filter keeps the primer clean, and because of their unique design, after wear the filter can be replaced without affecting the performance of the primer. The M-500 Series of trap seal primers do not require adjustment (except M3-500-NPB). They are engineered to deliver enough water to serve 3, 6, or 10 floor drain traps without adjustment. Also the “O” ring seals are tested for reliability at a temperature range of -40 degrees to 450 degrees F. All three models are listed with IAPMO and CSA and are tested and certified to the ASSE Standard 1018 and are so marked. U.S. Patent # 6,152,164.

Flush valve trap seal primers are installed below the flush valve and direct an amount of waste water discharged from the flush valve into a tube that connects to the floor drain trap to maintain the water seal. Their advantages are that the water used is already consumed by the flush valve operation, and this type of primer has no moving parts. Their disadvantage is that their location is determined by the location of the fixtures which may be too far away from the floor drains to be practical; Many installations cannot use flush valve trap seal primers because the floor drain traps are too far away to be reached by the flush valve trap seal primer.

Looking for something Electronic?

MIFAB also has that covered! MIFAB’s MI-100 series of electronic trap seal primers are a pre-assembled electronic trap seal primer system programmed to maintain the water seal of floor drain traps. It is made with an ASSE approved vacuum breaker, solenoid valve operated by a timer, shut off valve for maintenance. The MI-100 is engineered for equal distribution of water to all ports. like the M-500 it prevents the backflow of sewer gas, bacteria, and pests from crawling up. For the M-500 it is recommended to keep the trap seal primer close by, anything farther away than 20 feet could be an issue, as the farther the primer is away from the source of the pressure drop, the less likely it will sense it and work. The MI-100 on the other hand can be located anywhere in the building owner to adjust the frequency and amount of water delivery through a timer and stainless steel solenoid valve. The design of these primers is programmed at MIFAB’s factory with standard flush times. These flush times can be adjusted by the operator in order to discharge more or less water to the floor drain traps, depending on the installation and climate conditions. The MI-100 can be installed with a cabinet cover and capable of priming 1 to 30 floor drain traps. It is practical to serve many floor drain traps in infrequently used buildings such as convention centers and sports facilities.

Knowing which trap seal primer will work best for you is important, MIFAB is proud to offer all four types and if you need any more information please visit www.mifab.com.