In response to existing industry material deficiencies around HDPE, polypropylene, and polymer concrete, MIFAB has recently launched its new innovative Glass-Fiber Reinforced Polyester (GRP) channels that offer more stability than traditional plastic channels.

What is Glass-Fiber Reinforced Polyester (GRP)?

Glass Fiber Reinforced Polyester (GRP) is a composite material manufactured using glass-fiber reinforced polyester pressed from sheet molding compound (SMC). It is a composite of polyester resin, glass fiber mats and mineral fillers. The finished product offers high strength, excellent chemical resistance, high temperature resistance and a similar dimensional expansion and contraction property to Portland cement concrete. This last characteristic is critical to successful installations. GRP channels can sustain temperatures up to 212 degrees, which is more than HDPE, polypropylene and polymer concrete. Not only is it resistant to high temperatures, GRP is also resistant to most chemicals and acids making it an extremely reliable and versatile product in even the toughest conditions.

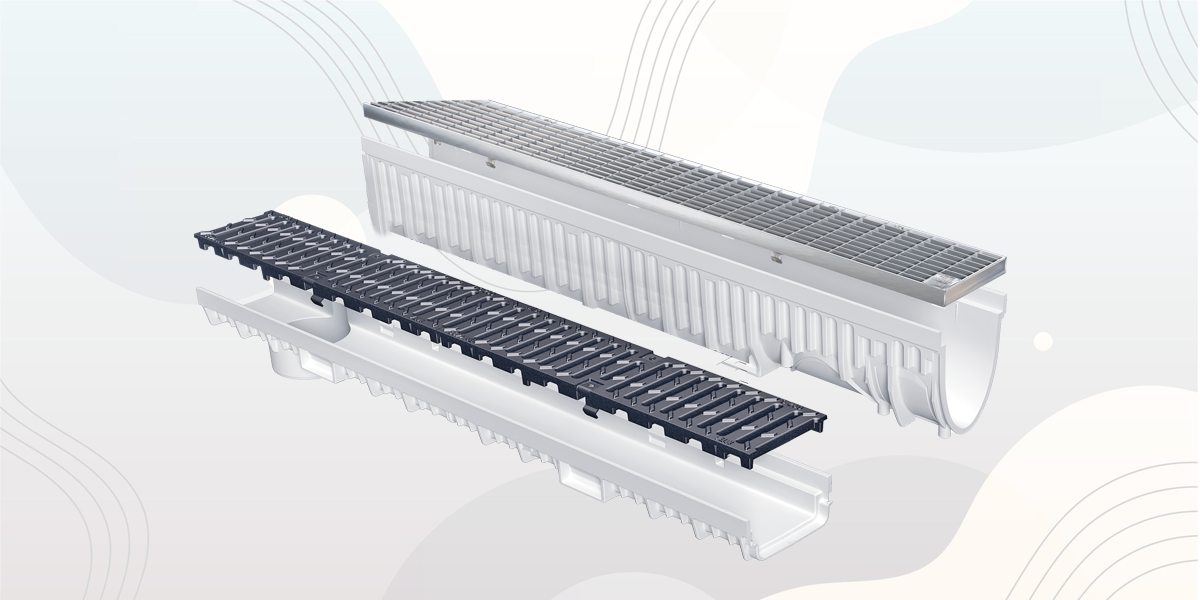

MIFAB’s innovative GRP channels are available in full meter or half meter lengths. Internal widths are available in 4″, 8″ and 12″ channels with and without slope. MIFAB offer channels without edge rails (up to Load Class C) as well as galvanized steel and stainless steel edge rails (up to Load Class E). Each channel has been designed and optimized for our universal Clipfix grate fixing mechanism with longitudinal shift protection. The systems can be completed with a wide variety of grates available in plastic, galvanized steel, stainless steel, and ductile iron. All grates are interchangeable across all channel materials MIFAB offers. Because of it’s material, our channels weigh 75% less than polymer concrete, allowing ease of installation.

Our innovative Clipfix grating systems offer an aesthetically pleasing solution when installed, no locking device or screws are visible and can be removed with a single hand movement. Grates are industry standard rated to EN1433 and available in load class A through E to provide a solution for all applications. MIFAB’s inclusive trench drain offering has several options for ADA compliant and heel proof grates available in different styles and materials. With the ability to stack more GRP channels, up to 85 pieces per pallet, there is a significant freight advantage and reduced breakage.

GRP channels are available in full meter or half meter lengths. Internal widths are available in 4″, 8″ and 12″ channels with and without slope. MIFAB offer channels without edge rails (up to Class C) as well as galvanized steel and stainless steel edge rails (up to class E). Each channel has been designed and optimized for our universal Clipfix grate fixing mechanism with longitudinal shift protection. The systems can be completed with a wide variety of grates available in plastic, galvanized steel, stainless steel, and ductile iron. All grates are interchangeable across all channel materials MIFAB offers.

MIFAB offers a full line of trench drain products and accessories. Visit our website at www.mifab.com to learn more about our GRP, Polymer Concrete, Industrial Stainless Steel, and Aluminum trench drain systems and to find out how Mifab is leading the industry with innovative trench drain solutions.